PingYang DEM Auto Parts Factory

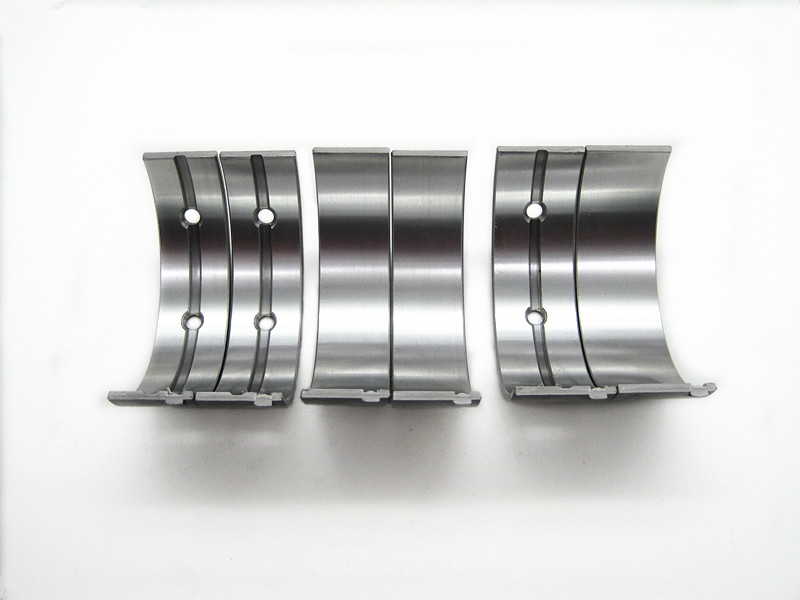

Pingyang DEM Auto Parts factory is a professional manufacturer of

engine bearing, piston ring, thrust , The products are used

for cars, trucks, generators, agricultural machinery, construction

machinery, internal combustion engines, etc., engaged in processing

and production for more than ten years, workers have rich

production experience and mature production technology, to ensure

the high quality of finished products and high requirements. We can

develop new items according to your samples or drawings, our factory has a large quantity of stock, can supply customers in

time.

It has passed ISO9001:2000 quality system certification,

measurement certificaton level III and standard administration

level IV. The comlpany is a comprehensive enterprise that combines

production,sales and service together,which adopts international

standardsand always pursues the tenet of" service, speed and

superiority". It is located in the major autoparts center

insouthern Zhejiangprovince-Yuyang Industrial Zone,with 104

National Road, Tongsan expressway and Wenfu Railway arel

runningthroughsouthto north, only 40 kilometers fromWenzhou Airport

and Wenzhou Railway Station. It manufactures over700 types of

engine bearings, with an annual output of more than 3million sets,

including those for equipments with high requirements on

precisionand technology,such as engineering machineries,ships and

refrigerators,as well as those for motorpartsof special

specifications such asl special engine bearings, bushes,thrust

washers,piston rings,water pumps and so on. With perfect quality,

advanced technology and fine craftwork, ourl company is willing to

cooperate with our old and new customers at home and abroad to

develop with the time hand in hand.